SkyWay Group was started by Sierra Industries of Uvalde, Texas. Established in 1983, Sierra Industries rapidly built up a catalog of more than 300 FAA-approved Supplemental Type Certificates (STCs) for a variety of aircraft modifications.

Many of the most significant are for successful turbine re-engining and aerodynamic modifications to improve the performance, reliability and safety of multiple business jet models. These include the Cessna Citation 500/501, 550 and S550 series, as well as Beechcraft 400 and 800 models.

To date, more than 150 re-enginings have been performed, giving SkyWay Group’s engineering team a vast reservoir of expertise in jet aircraft modification.

The team’s familiarity with STC development, flight testing and flight test bed development helps streamline the FAA approval process, substantially reducing time-to-market. Well-supported relationships with suppliers and partners is also essential to our success. Previous development program partners include such well-known aerospace organizations as:

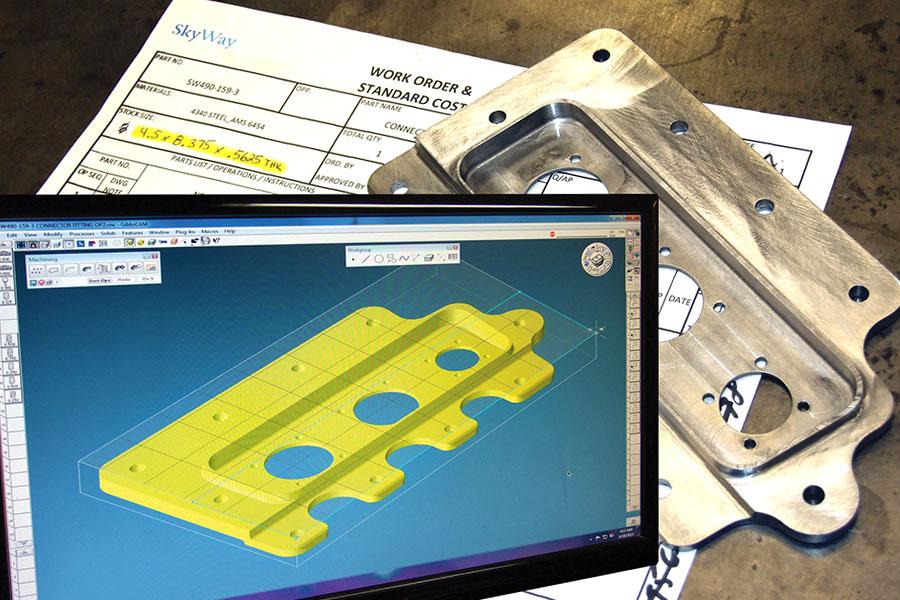

A PMA-certified in-house machine shop and experienced fabrication team help to support both R&D efforts and manufacturing for SkyWay’s aircraft upgrades. Sophisticated CNC machining and assembly tools are utilized to speed the development process and provide product support to our customers.

In-house sheet metal capabilities, fully trained and qualified A&P mechanics, and on-field access to paint and interior facilities provide a convenient “one-stop” solution for maintenance, repair and modifications.